Furnace Heaters

Furnace heaters are the heaters found in industrial furnaces. These

products perform the function of quickly heating the materials inside the furnaces

to the intended temperature. As a result, the material in the furnace can

remain at the intended temperature for the intended amount of time. They are

products that can be used in a variety of industries, including the iron and

steel industry, ceramic production, lime production, cement production, and

glass production.

Industrial furnace heaters are used in furnaces that are used in the industrial

production phase. These products can do more than just heat. They can also melt

and cook. These products, which are also known as industrial furnace heater,

operate on different principles depending on their intended use. In other

words, we can provide constructive solutions to your needs with furnace heaters

tailored to various industries.

Furnace Heaters Technical Specifications

• Furnace Heaters can perform at temperatures as high as 1400 degrees.

• These furnaces

provide the processing of chemically reacting industrial materials.

•Heaters with a working capability of more than 400 degrees are in the

furnace heaters class.

• The heating process

in furnaces starts with the thermostats sending electrical signals to the

relays inside the furnace.

• These heaters can

operate at high performance for many years under harsh conditions. When a part

fails, a part replacement is usually recommended for its former performance.

• Furnace heaters are

produced from metal wire and carbon materials.

• Tube type heaters up to 500 degrees, spiral winding heaters and radiant tube heaters up to 1300 degrees, silicon carbide heaters up to 1400 degrees, molybdenum disiliside, heaters up to 1700 degrees are used in furnaces.

What are the Usage Areas of Furnace Heaters?

In industrial production areas, furnace heater is used. These furnaces are also required in areas where even high metals can be melted or shaped, such as the glass industry or a variety of other manufacturing sectors. It is used to work at high temperatures as well as to heat industrial furnaces.

In the industrial kitchen, furnace heaters are also used. It provides a very practical and qualified solution especially in kitchen areas that produce intensively in the industrial area. They are ideal solutions for businesses that need a smaller furnace. Furnaces with furnace heaters serve vital functions in the preparation of delectable dishes. You can select a furnace with the features you require based on your restaurant's menu.

What Are the Advantages of Furnace Heaters?

The most important advantage of furnace heater is that it allows for faster production. It enables the material to be controlled in environments where high temperatures are required. Because processing and controlling a material at high temperatures is a very difficult process. Because of bakery restaurants, materials can be controlled in furnace heaters to fulfill a specific function. In other words, businesses benefit from both cost and time savings.

For intended jobs, industrial type furnaces with furnace heaters can be used. This provides significant labor force and time savings. It assists you in operating the furnace at the intended temperature and function. Because they come in a variety of sizes and features, these products provide very accurate solutions. At the same time, it allows you to keep up with heavy orders in industrial facilities for many years without maintenance.

Furnace Heaters Prices

Furnace Heater prices vary according to the size, technical features,

and functions of the product. Our customers place

orders for various products based on the area and volume of business in their

manufacturing facilities. That is why, rather than providing a firm price

offer, we first learn about your requirements. We prepare a price offer for you

after learning about your requirements. You can contact us right away for

information and advice on furnace heater. Furthermore, our team can come to

your home and conduct a free discovery. We complete the production of the

furnace heater that we have specially designed for you in a timely manner, and

we make every effort not to disrupt your production process

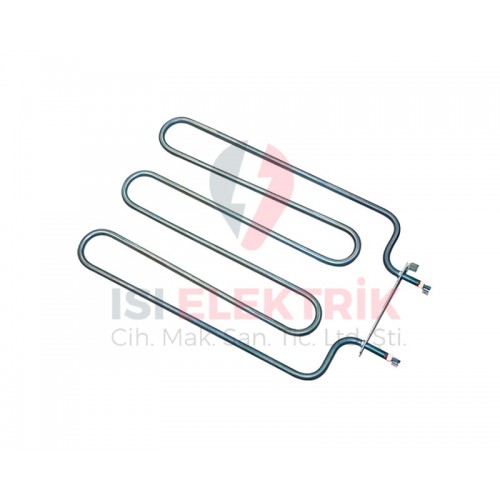

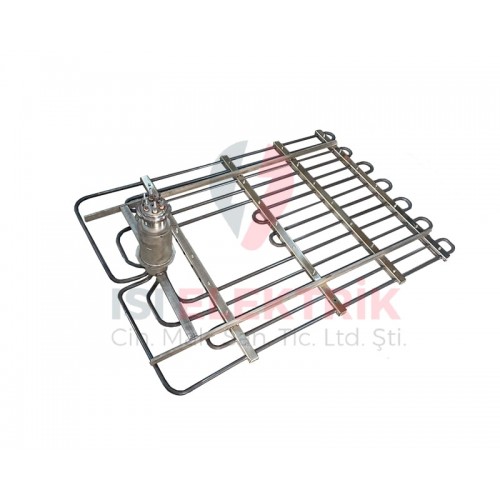

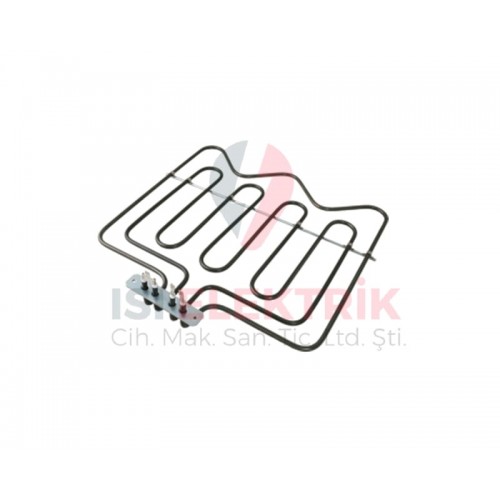

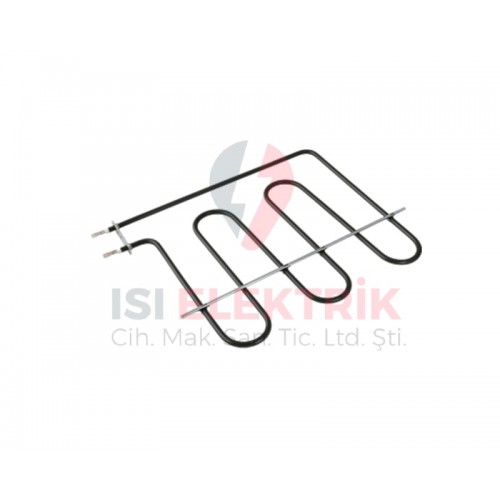

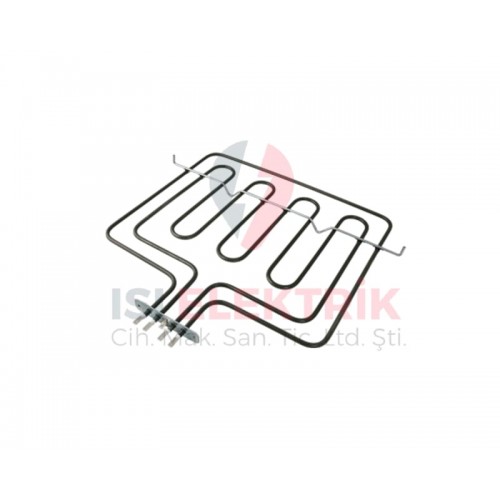

Heater Elements for Furnaces

Heater elements, also known as furnace heaters, are electric devices found inside furnaces that generate heat to cook food. Heater elements can be found at the bottom, top, or both sides of the furnace.

Heater elements come in two main types:

- Bottom Heaters: Bottom heaters are located at the bottom of the furnace and are used to cook the bottom part of the food.

- Top Heaters: Top heaters are located at the top of the furnace and are used to cook the top part of the food.

Types of Furnace Heater Elements

- Ceramic Heaters: Made from ceramic materials, these types of heaters are resistant to high temperatures and are generally used to distribute heat more evenly inside the furnace.

- Quartz Heaters: Quartz heaters are preferred for their quick heating and cooling properties. They can withstand high temperatures and are effectively used inside furnaces.

- Semiconductor Heaters: These heaters are typically used for industrial furnaces. Made from semiconductor materials, these heaters are resistant to high temperatures and are usually designed to meet specific cooking requirements.

Technical Specifications of Furnace Heater Elements

- General Technical Specifications:

- Power: Available in different power levels ranging from 500 watts to 3000 watts.

- Electric Voltage: 220 volts or 240 volts.

- Temperature Range: Can be used within various temperature ranges from 50°C to 500°C.

- Diameter: Available in various diameters ranging from 8 mm to 20 mm.

- Length: Available in different lengths ranging from 100 mm to 1000 mm.

- Body Material: Can be made of various materials such as stainless steel, aluminum, or cast iron.

- Heating Element Material: Can be made of different materials such as nickel-chromium, stainless steel, or Inconel.

- Protection Class: Available in different protection classes such as IP20, IP44, or IP65.

- Connection Type: Available in different connection types such as butterfly nut, cable connection, or plug connection.

- Other Technical Specifications:

- Heating Speed: How quickly the heater element heats up.

- Cooling Speed: How quickly the heater element cools down.

- Heat Distribution: How the heater element distributes heat.

- Lifespan: How long the heater element can last.

Advantages of Furnace Heater Elements

- Flexibility and Variety: Furnace heater elements can be produced in different sizes, shapes, and power levels, providing solutions suitable for different types of furnaces and application needs.

- Homogeneous Heat Distribution: Quality furnace heater elements provide homogeneous heat distribution inside the furnace, ensuring that food or processed materials are cooked or processed evenly.

- Reduced Carbon Emissions: Electric furnace heater elements produce fewer carbon emissions compared to furnaces that operate with natural gas or coal, contributing to reducing environmental impact.

- Easy Installation and Maintenance: Furnace heater elements generally require easy installation and maintenance. When replacement is needed, removing the old heater element and installing a new one is usually straightforward.

- Less Odor and Smoke: Electric furnace heater elements produce less odor and smoke compared to furnaces that operate with gas or coal. This improves indoor air quality and provides a more comfortable atmosphere in workplace or home environments.

Materials Used in Furnace Heater Element Production

- Body Material:

- Stainless Steel: Stainless steel is the most commonly used body material for furnace heater elements. It is durable, corrosion-resistant, and easy to clean.

- Aluminum: Aluminum is lightweight and resistant to corrosion. It is less commonly used in furnace heater element production.

- Cast Iron: Cast iron is sturdy and durable. It is less commonly used in furnace heater element production.

- Heating Element Material:

- Nickel-Chromium: Nickel-chromium is the most commonly used heating element material for furnace heater elements. It is durable, can withstand high temperatures, and has a long lifespan.

- Stainless Steel: Stainless steel is corrosion-resistant and easy to clean. It is less commonly used in furnace heater element production.

- Inconel: Inconel is resistant to high temperatures and corrosion. It is an expensive material and is used in special furnace heater applications.

- Insulation Material:

- Ceramic: Ceramic can withstand high temperatures and provides good insulation. It is the most commonly used insulation material in furnace heater element production.

- Mica: Mica can withstand high temperatures and is flexible. It is less commonly used in furnace heater element production.

- Connection Elements:

- Butterfly Nut: Butterfly nuts are used to secure the furnace heater element to the furnace.

- Cable Connection: Cable connections are used to connect the furnace heater element to the power source.

- Plug Connection: Plug connections are used to easily attach and detach the furnace heater element.

Technical Details to Consider When Choosing Furnace Heater Elements

- Technical Details to Consider When Selecting Furnace Heater Elements

- Power: The power of the heater element should be chosen according to the size of the furnace and the intended use. Larger furnaces require more powerful heater elements.

- Voltage: The voltage of the heater element should match the voltage of the furnace's electrical system.

- Temperature Range: The temperature range of the heater element should be selected based on the foods to be cooked. Different cooking processes require different temperatures.

- Body Material: The body material of the heater element should be selected according to the environment inside the furnace. Stainless steel is the most common choice due to its resistance to corrosion and ease of cleaning.

- Heating Element Material: The heating element material should be heat-resistant and long-lasting. Nickel-chromium is the most commonly used heating element material in furnace heater elements.

- Protection Class: The protection class of the heater element should be chosen according to the environment inside the furnace. Heater elements that provide protection against factors such as water and dust should be preferred.

- Connection Type: The connection type of the heater element should be selected according to the model and brand of the furnace. Different connection types, such as butterfly nuts, cable connections, or plug connections, are available.

- Size: The size of the heater element should be suitable for the interior of the furnace. The heater element should have sufficient space inside the furnace and should not come into contact with the food.

- Additional Features: Some furnace heater elements come with additional features such as thermostats, timers, or cooking programs. These additional features can make the cooking process easier and more controlled.

Furnace Heaters