Heater Powder

Heater powder is a very special material used during the production of heaters. These products are non-conductive and have extremely high heat resistance. Also known as magnesium oxide (MgO), heater powder is used during the manufacturing process of heating elements. One of its most notable features is its lack of electrical conductivity. After passing the testing phase during heater production, these products are released for sale according to specific manufacturing standards. The powders vary in different characteristics.

MgO Heater Powder

MgO heater powder is commonly used in the production of cartridge and tubular heaters. We have three different types of 25 kg packages available in stock.

High Temperature: High-Grade MgO (1100°C)

It is used in the production of cartridge heaters and high-grade furnace heaters. This type of powder is capable of withstanding temperatures up to 1100°C, making it suitable for high-temperature heating applications in industrial environments.

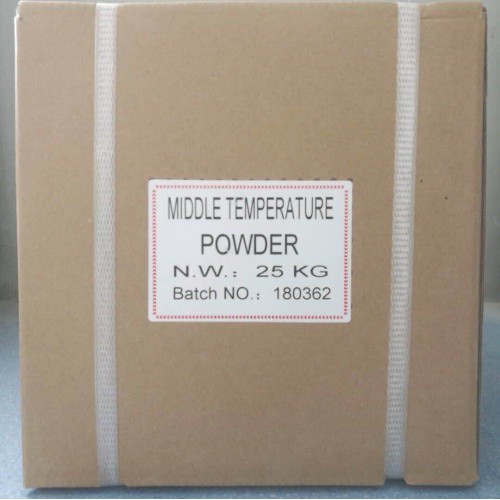

Middle Temperature: Medium-Grade MgO (900°C)

Used in dry environment heaters, high-temperature liquid heaters, and serpentine heaters. This medium-grade powder can withstand temperatures up to 900°C and is widely used in various industrial heating processes.

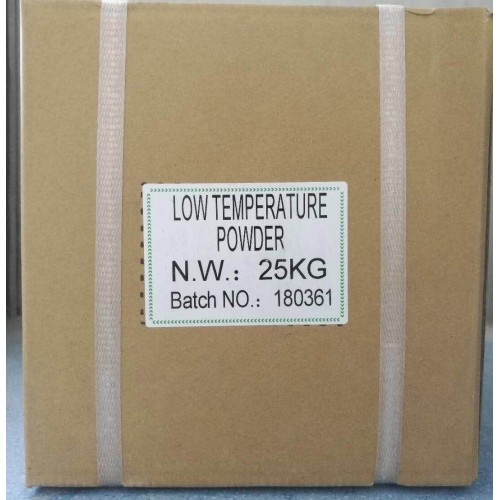

Low Temperature: Low-Grade MgO (700°C)

This type of powder is used in heaters that are designed to heat water and low-temperature liquids, making it ideal for applications where lower temperature levels are required. It is used in applications such as water heaters and other low-temperature heating devices.

Our low temperature MgO resistance powder is made of electrofused magnesium containing more than 93% MgO, it is calcined at high temperature and finally additives are added. The product has the following features:

Temperature resistance:Excellent electrical performance, low leakage current in low temperature conditions, and should be widely applied to low temperature heating elements, mostly for domestic appliances use.

Filling effect: Good flow properties, better density when filled into the heat pipe, hence a good thermal effect.

Our Medium Temperature MgO resistance powder is made of electrofused magnesium containing more than 97% MgO, it is calcined at high temperature and finally additives are added. The product has the following features:

Temperature Resistance: Excellent electrical performance, low leakage current under medium temperature conditions, High safety, widely applied to medium temperature heating elements.

Filling Effect: Good flow properties, better density when filled into the heat pipe, hence good thermal effect.

Our High Temperature MgO resistance powder is made of magnesium containing more than 98% MgO, which is electrofused first, additives added second, and molten by high temperature calcinations third. The product has the following features:

Temperature resistance: Excellent electrical performance, low leakage current under high temperature conditions, High safety, widely applied to air-heating elements. It provides very good efficiency especially in cartridge resistances.

Filling effect: Good flow properties, better density when filled into the heat pipe, hence good thermal effect.

Heaters Powder Varieties

- Nickel-Based Heaters Powder: Produced based on nickel oxide (NiO). Commonly used in electric heating systems, furnaces, and casting processes.

- Iron-Based Heaters Powder: Contains iron oxide (Fe2O3). Widely used in the metallurgy industry and iron-steel production.

- Chrome-Based Heaters Powder: Contains chromium oxide (Cr2O3). Used in metal processing, glass production, and ceramic industry.

- Platinum-Based Heaters Powder: Used in fields requiring high precision such as laboratory equipment and medical devices, albeit costly.

- Ceramic Heaters Powder: Utilizes the high temperature resistance and electrical resistance properties of ceramic materials. Used in industrial furnaces and glass production.

Heaters Powder Technical Specifications

- Chemical Composition: MgO

- Appearance: White powder

- Melting Temperature: 2800°C

- Density: 3.58 g/cm³

- Mohs Hardness: 5.5

- Thermal Expansion Coefficient: 13.0 x 10^-6 °C^-1

- Dielectric Constant: 9.6

- Thermal Conductivity: 50 W/mK

- Electrical Resistance: > 10^12 Ωm

Industrial Applications of Heater Powder

- Electric Heating Elements: It is widely used in industrial furnaces, ovens, heating systems, and equipment. In such devices, heater powder plays a critical role in improving the efficiency of heating elements and optimizing energy consumption. This material, with its high thermal resistance, enhances the performance of electric heating systems and ensures long-term durability.

- Metallurgy and Metal Processing: It is frequently used in metal melting furnaces and casting processes. In the metal processing industry, heater powder helps in the effective use of metal oxides at high temperatures, allowing faster and more efficient metalworking processes. Additionally, it ensures uniform heating during metal surface treatments, resulting in high-quality outcomes.

- Chemical Industry: It is used to provide heat in chemical reactors and evaporation systems. Heater powder helps control temperatures in chemical production processes, ensuring optimal reaction conditions. This material also contributes to the longevity of heating elements used in chemical reactors, facilitating efficient and safe chemical reactions.

- Glass and Ceramics Industry: It is commonly used in glass melting furnaces and ceramic firing kilns. In glass production, high temperatures are required to melt the glass, and heater powder helps optimize the performance of furnaces, minimizing energy consumption. In ceramics, it ensures consistent heating in kilns, resulting in high-quality ceramic products.

- Medical and Laboratory Equipment: It is used in high-temperature sterilization and heating processes. Heater powder helps maintain stable and controlled temperatures in medical devices and laboratory equipment, which is crucial for sterilization processes. Its high thermal resistance ensures safe and effective results during these sensitive operations.

- Food Industry: It is used in ovens and heating facilities for baking or processing food products. In the food industry, heater powder plays a key role in ensuring uniform cooking and processing by providing efficient heat transfer. Its high thermal conductivity contributes to the consistent heating of food products, improving the overall quality of the final product.

- Automotive Industry: It is used in the production of heating elements and catalytic converters. In the automotive industry, heater powder helps efficiently heat exhaust systems and catalytic converters, contributing to reduced emissions and improved fuel efficiency. It is also used in vehicle interiors to provide comfortable heating environments for drivers and passengers.

What Materials Make Up Heater Powder?

- Nickel Oxide (NiO): Nickel oxide is one of the primary components of heater powder and is resistant to high temperatures. It is known for its electrical resistance properties and is commonly used in electric heating applications. Nickel oxide provides high thermal durability and long-term stability, making it ideal for high-temperature industrial processes.

- Iron Oxide (Fe2O3): Iron oxide is another essential material found in heater powder. It has heat-resistant and electrical resistance properties. Iron oxide is often preferred in cost-effective applications and is widely used in metallurgy and steel production, where it contributes to durable heating elements.

- Chromium Oxide (Cr2O3): Chromium oxide may be present in heater powder, contributing to its resistance to high temperatures. Chromium oxide helps increase the thermal resistance of the heater powder, making it suitable for applications requiring high heat tolerance, such as glass and ceramics industries.

- Other Additives: Heater powder can also contain other additives. These additives are used to enhance specific properties or improve the processing of the powder. For instance, materials that increase heat resistance, elements that enhance electrical resistance properties, or chemical compounds that facilitate processing can be added. These additives ensure that the powder is optimally used in various industrial applications.

Features of Heater Powder Providing High Heat Efficiency

Heater powder offers excellent heat transfer efficiency and high thermal conductivity, making it ideal for industrial heating applications. These powders minimize heat loss while providing energy-efficient heat transfer. When mixed with heating elements, they efficiently transfer heat and reduce energy consumption. Their high-temperature resistance allows them to work more effectively, preventing energy waste and providing more heat with less energy consumption.

Heater powders are ideal for high-temperature applications such as industrial furnaces, chemical reactors, and metal processing systems. These powders transfer heat effectively due to their electrical conductivity properties, ensuring efficient heat distribution. Furthermore, they guarantee high efficiency with lower energy consumption, helping to reduce operational costs.

Technical Details to Consider When Choosing Heater Powder

- Thermal Conductivity: Heater powder's high thermal conductivity efficiently transfers heat and prevents energy loss.

- Temperature Resistance: The maximum working temperature of the powder is crucial to ensure optimal system performance.

- Electrical Resistance: High electrical resistance ensures safety by preventing short circuits and minimizing energy loss.

- Chemical Stability: The chemical composition of the powder should be resistant to temperature fluctuations and aggressive environments.

- Density and Particle Size: The powder's density and particle size affect its thermal conductivity. Smaller particles generally provide better heat conduction.

Working Principle of Heater Powder

When combined with heating elements, heater powder functions as a high-resistance material that generates heat when electric current passes through it. The powder efficiently transfers heat and ensures uniform heating. During operation, these powders remain stable even at very high temperatures, which is crucial for long-lasting and safe use.

The working principle of heater powders focuses on thermal conductivity and electrical resistance. As current passes through the powder's high-resistance structure, it is converted into thermal energy, which is then distributed throughout the system. Thanks to their high temperature resistance, these powders provide efficient heating over extended periods, ensuring energy savings despite temperature fluctuations.

Frequently Asked Questions

Mgo Powder